Yamazaki Mazak will exhibit its latest development in CNC systems, alongside 21 advanced machines at JIMTOF 2014.

From innovative hybrid machining technology to the latest laser processing machines, Mazak will be showcasing a range of manufacturing solutions and applications expertise at the exhibition, due to be held in Toyko from the 30th October – 4th November.

Visitors to the Mazak stand will be able see 21 highly advanced machine tools in action, including five standout multi-tasking machines from its INTEGREX range, two of which will be making their debuts: the INTEGREX j-200S and INTEGREX e-1600V/10S.

A total of 7 models will also feature the new high-performance MAZATROL SmoothX CNC; which is the seventh generation of Mazak’s MAZATROL controls. Alongside Mazak’s new machining centres and CNC control system, the company will be unveiling two new hybrid machines. Shown for the first time in Japan will be the VTC-530/20 FSW, which incorporates the Airbus Innovation Group-developed DeltaN FS friction-stir welding capability, which enables the machine both to machine and join a range of high performance materials in one platform.

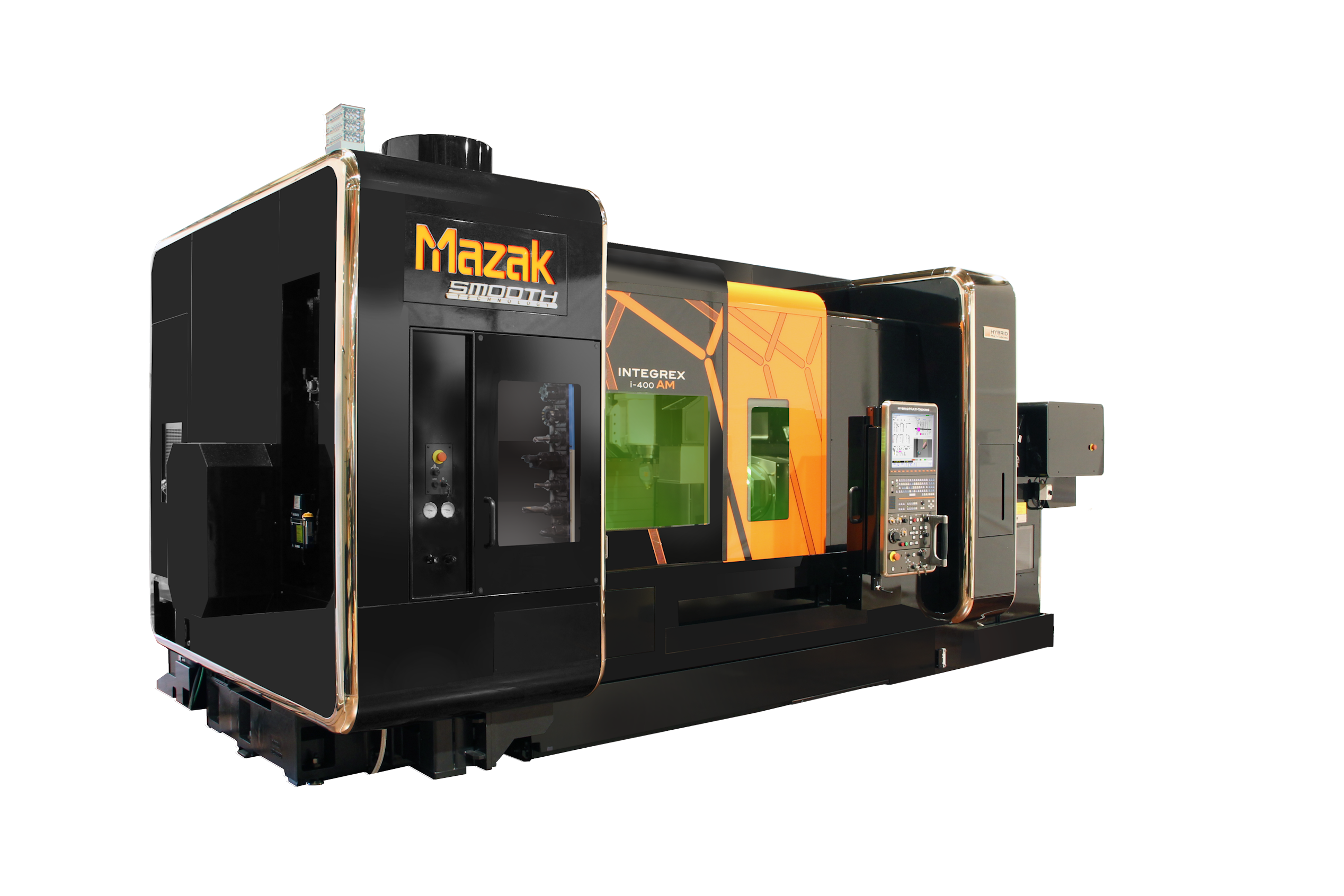

The second hybrid machine on debut will be the INTEGREX i-400 AM, which integrates additive manufacturing technology onto a state-of-the-art multi-tasking machine. This new machine will provide near net shape feature generation, with high accuracy 5-axis machining capability, which as a result significantly reduces production lead time for complex components across a range of industry requirements.

A number of laser processing machines will also be on display, including the OPTIPLEX 3015 FIBER II, and the new 2D Tube Gear 150, designed for efficient, high-speed tube and pipe laser cutting operations which require high levels of precision.

For further information on Mazak at JIMTOF please contact your local Mazak representative.